Metalsider’s Foundry is considered as state of the art in process technology. Structured under the unprecedented concept of verticalization, the production of castings relies on pig iron and electrical energy produced within the industrial complex.

The facilities have a modern design and the best solutions in machines and equipment available in the market and a highly qualified technical team with extensive experience in iron casting.

TECHNOLOGY

Metalsider Foundry uses cutting-edge MAGMASOFT and SOLIDWORKS softwares for the development of parts, tools and solutions.

"In House" use of optical emission spectrometer for chemical composition verification LECO: instantaneous analyzer of 'C and S.

It also has Dimensional, Metallurgical, Mechanical and Sand Laboratories: capacity to perform all standard sand laboratory tests. Strategically located near the preparation and molding line: pH, humidity, temperature, fire loss, compactability, bentonite test.

Dimensional: DEA Global performance Metallurgical: Axiovert 1000X Zeiss microscope with image analyzer Benchtop durometer DIGIMES: 4 politrizes 1 cutter samples cold sample inlay system.

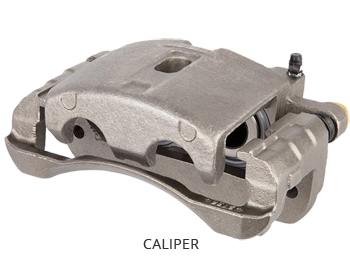

PRODUCTS

Main products of METASLIDER FOUNDRY:

Brake Calipers, Differential Casings, Transmission Casings, Seering Knuckles, , Engine Supports, Wheel Hub, Crankshafts, spider Brakes, Brake Drums, Brake Discs, flywheels , Railway application parts.

Product classes for CAST IRON

NODULAR: GGG 40, GGG 50, GGG 60, GGG 70 - GRAY: GG 20, GG 25, GG 30